Jackson pickup were manufactured by Grover Jackson and company from the time of the San Dimas shop. The made in USA pickups were used on import Charvels as well as all Jackson product. Most of the Jackson employees that were hired to wind pickups were women. This is because women have a greater tolerance for this very meticulous process. Men generally have less patience for a process such as winding pickups.

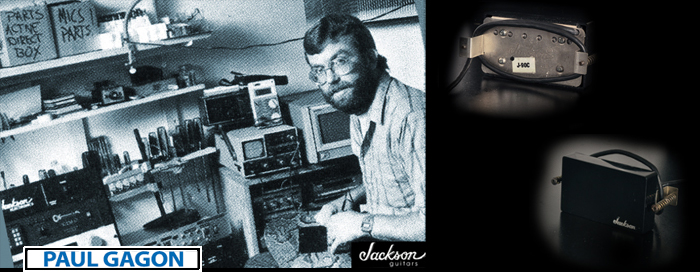

Jackson pickups were manufactured exclusively in the USA and in-house at the Jackson shop for years. Jackson Manufacturing introduced many pickups and electronics innovations with the help of the employee Mr. Paul Gagon. The line of Jackson USA Pickups were made in the USA through to the Ontario California period.

In 1989 Jackson branded pickups started to be outsourced to Gotoh Japan. That said, the USA shop continued to research, develop, produce and manufacture pickups for USA made guitars and higher end Japan made Jackson guitars well into the 1990s.

The made in Japan Jackson Pickups seemed to have been placed initially in import Jackson Charvel guitars starting about 1989. The made in Japan Jackson branded pickups from all accounts were made with the exact same formula as the made in the USA Jackson pickups just produced in Japan.

The picture below shows a 1990 import Jackson pickup sticker that has had a handwritten "D" added to J-50B model identification.

These stickers looks as if a "C" has been removed from the end.

Indeed the "C" was removed and the "D" at the beginning was hand written to these pickups. The handwritten '"D" stands for domestic ( if you were in Japan it was domestic ) and the "C" was removed assumingly because of a shortage of stickers at the Gotoh Japan plant. Thus a J-90C label was used on a J-90 pickup by cutting off the "C". Oh yes, and a J-90 without the "C" would be a J-90 with alnico magnets. A J-90C would have ceramic magnets.

The photo below shows a 1986 pickup that was made in the USA and used in a Model 2 Charvel. To the right we have a 1994 import Jackson Japan made pickup. Between 1989 and 1992 there is evidence that Gotoh Japan and Jackson Ontario California were sharing the same labels ( or labels that appear to be the same ) and placing the labels on the back of the pickups to designate the pickup model numbers. By the mid-1990s Gotoh was making near to all Jackson branded pickups that were used on Jackson and Charvel import guitars. This seems to correspond to USA made Jackson pickup production slowing and eventually stopping completely.

One additional note is that after 1990 the import Jackson branded pickups had numbers in addition to the model # on the labels. Numbering such as "9.8", "10.2", "10.8" indicate pole piece pitch distance in millimeters and do not indicate pickup readings.

Jackson Pickup Information

Paul Gagon Pickup Designer for Grover Jackson

Paul Gagon was responsible for the working with Grover Jackson to ensure the successes of Jackson pickups and electronics. The following is a description of this period for Jackson Charvel pickup history in the words of the great Paul Gagon. The following interview can be found here in Pauls Biography.

I was very fortunate to have met Grover Jackson around 1984. We quickly hit it off and became close friends. When my time at Fender had come to a close, it only took one phone call to my buddy Grover Jackson and I was set. Next stop, Charvel/Jackson and the ride of my life.

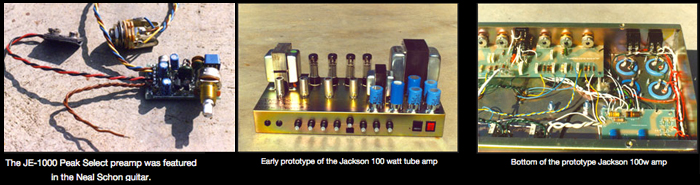

Working with Grover at Charvel/Jackson was like strapping myself onto a rocket. Everything was moving at high speed. At any given time, some amazing guitar player would just show up to hang out at the shop and talk about guitars, amps, pickups, effects, whatever. Next thing I know, I’m designing and building a guitar switching pedal for Steve Vai, next it’s an effects rack switching bank for Vinnie Vincent, then up to San Francisco to hand deliver a custom tube guitar preamp to Neil Schon of Journey. One of the highlights of this type of crazy, high speed, life style was finding myself in a hotel room with Jeff Beck and his manager showing Jeff a new guitar-to-midi converter that we were developing under the Charvel name. I remember thinking to myself……I’m hanging out in Jeff Beck's hotel room…….how on earth did I ever get here?

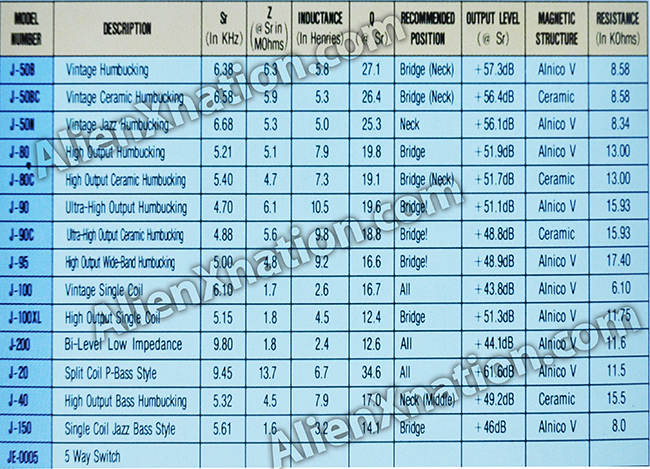

There were many projects to be undertaken at Jackson. First up, design a line of guitar and bass pickups. Since I had just spent 5 years at Fender R&D working on pickup design, I had a good background to work with. That experience, coupled with tearing apart every single pickup that was on the market at the time to extract their specs, gave me a pretty good place to start. My goal was not to design what I thought was the best sounding pickup but to design what the arena of rock stars that regularly marched through the Jackson plant wanted. The needs of all these heavy metal gunslingers varied quite a bit, so we decided to make several pickup models that would cover 90% of what they wanted. I regularly carried two briefcases with me that each contained around 30 humbucking pickups. One briefcase held pickups that used alnico magnets and the other briefcase held pickups that used ceramic magnets. These pickups varied in their magnet wire gauge and number of turns. I can’t even begin to tell you how many hundreds of hours I spend soldering in pickup after pickup in countless artists' guitars to find that “Magical One."

After Grover and I had defined what our line of pickups would be, we hit the road and visited our Charvel/Jackson dealers all along the west coast from Seattle Washington to San Diego California. We conducted clinics we called “Jackson Pickups…..what you should know.” These clinics allowed music store owners to bring in their customers so they could ask us questions about how pickups work and why they sound the way they do. During this adventure, I realized just how little most players really understood about the most important part of an instrument's sound: the pickups.

After Grover and I had defined what our line of pickups would be, we hit the road and visited our Charvel/Jackson dealers all along the west coast from Seattle Washington to San Diego California. We conducted clinics we called “Jackson Pickups…..what you should know.” These clinics allowed music store owners to bring in their customers so they could ask us questions about how pickups work and why they sound the way they do. During this adventure, I realized just how little most players really understood about the most important part of an instrument's sound: the pickups.

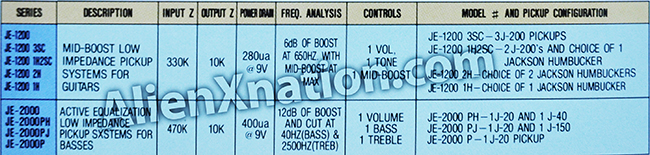

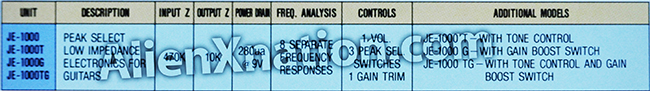

The next project was a line of guitar electronics that included buffer/preamps with pickup loading controls, treble/bass boosters, and mid-boosters. These, along with the new line of pickups, were all placed under the banner of Jackson Electronics. We also made active direct boxes, signal distribution systems, tube preamps, and a 150 watt rack-mount power amp. A few of these items never went into large scale production, but they were all important to the learning process of the company just the same.

Towards the end of the eighties Charvel/Jackson merged with IMC of Texas. This merger gave me the additional assignment of developing a line of both tube and solid state amplifiers. I started by designing 50 and 100 watt tube heads that were based on early Marshall amps.These amps marketed under the banner of Jackson Amps. The solid state line of amplifiers covered the range from a 200 watt bass head, 120 watt channel switching guitar amp, and went all the way down to a tiny little 5 watt screamer. The solid state line carried the name of Charvel. Charvel amp launch at NAMM; I believe this was in '87.

By the end of 1990 it was looking like my time at Jackson was coming to a close. IMC had already pushed Grover out of the organization and since I was not willing to move my family to Texas, I was released as well. >> End Paul Gagon Biography Quote